Biomass and Waste to Energy Systems

Among the main solutions for the protection of the environment within a context of sustainability and durability, we need to eliminate the waste generated by human activity and to reduce the use of fossil fuels in order to contribute to a reduction of the greenhouse effect. One solution is the energy recovery of waste and biomass.

At AA and Partners, we specialize in designing and integrating smart solutions, building and operating innovative facilities for the energy recovery of all types of waste and biomass and obtaining renewable and sustainable energy in the form of heat, cold, electricity or fuel.

Depending on the type of waste and/or biomass (urban waste, wood, agriculture, livestock, agrifood, industrial waste, etc.), we design innovative solutions to convert the raw material and use it as:

- Bioenergy (via incineration, gasification …): electricity, heat and/or cold for urban heating networks or for industrial processes.

- Biofuel (bioethanol, biodiesel, jetfuel and biogas).

We deem the AA and Partners technology the best technical and economical solution for the challenges of the presence and the future: the energy production from renewable sources as well as the effective recovery of energy from residual and waste materials and their environmental friendly disposal. We offer tailor-made solutions with the most suitable process meeting exactly the requirements of the specific case.

Our fluidized bed plants dispose solid, pasty and liquid materials thermally and recover the energy from these materials. Excellent operation results are obtained without any additional valuable fossil energy by our outstanding process even when using low caloric waste materials. So the demands for sustainability are fully met.

Solid residuals and waste are utilized at high temperatures by means of our rotary kiln – if the characteristics of the waste do not require a fluidized bed system. In combination with a downstream combustion chamber liquid residuals and waste can be utilized, too.

Liquid and gaseous residuals and waste are utilized by means of our Static Incineration chamber.

Fluidized Bed Incineration Systems

FBI Technology stands for a highly specialized fluidized bed incineration technology which has been developed further significantly and new application fields have been identified.

We design and construct fluidized bed incinerators and waste heat steam boilers for power generation, for energy recovery and for environmentally friendly thermal disposal.

According to our company’s philosophy we offer solutions which meet exactly the individual requirements of our clients and which are the best choice with regard to technology, economy and efficiency.

We design and construct fluidized bed incineration plants for:

- Power generation

- Energy recovery

- Chemical processes

- Environmentally friendly thermal utilization and disposal

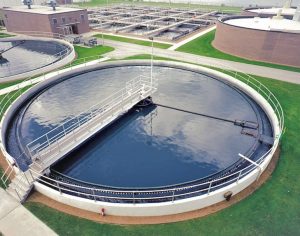

- Sewage sludge, coal sludge and waste sludge from industry and refineries

Rotary Kiln

A Rotary kiln is a pyroprocessing device used to raise materials to a high temperature in a continuous process, AA and Partners has applied such technology for solid waste incineration in combination with static (second) incineration chamber.

Static Incineration Chamber

Static incineration chamber mainly used for liquid and off gas treatment.

Catalytic Oxidation Systems

Catalytic oxidation is an alternative to common off gas incineration for the treatment of VOCs in air or N2 streams resulting from remedial operations. The addition of a catalyst accelerates the rate of oxidation by adsorbing the oxygen and the contaminant on the catalyst surface where they react to form carbon dioxide and water. The catalyst enables the oxidation reaction to occur at much lower temperatures than required by a conventional thermal oxidation. VOCs are thermally destroyed at temperatures typically ranging from 320° to 540° C by using a solid catalyst. First, the contaminated air is directly preheated (electrically or steam, more frequently, using natural gas or propane) to reach a temperature necessary to initiate the catalytic oxidation (310 °C to 370 °C) of the VOCs. Then the preheated VOC-laden air or N2 is passed through a bed of solid catalysts where the VOCs are rapidly oxidized.

Process Modules&Components

Proven and tested systems in various applications with high reliability, gain valuable time fabricating skid mounted units parallel to construction work with the ability to run full factory acceptance tests (FAT’s) prior to shipment.

Vacuum Module

Vacuum is required in a wide range of industries, in the chemical- and pharmaceutical industry vacuum systems have an even higher importance because some of the gases maybe very toxic or corrosive. In addition vacuum pumps are a constant source of ignition and dangerous when not adequately designed, installed or operated and require a well-thought-out design and control system.

Dead Leg Free Sample Valve

This is a value engineered sample valve which was created for a large multipurpose API tank farm with the requirement for a minimum hold up. It is full made from full PTFE body and valve seat is made in Hastelloy C quality. A very compact sample valve which has been successfully installed and operated in several API plants.